DESCRIPTION

Brake system is hydraulically operated, using a tandem master cylinder and a Master-Vac power brake unit. Front brakes are Girling-Sumitomo dual piston fixed caliper type. Rear brakes are leading-trailing, shoe/drum type. Brake system is equipped with a combination valve to prevent premature locking of rear wheels. A brake warning light works off the combination valve and indicates when a pressure drop occurs in either front or rear circuit. Parking brake is mechanically actuated through cables and levers. Parking brake locks rear drum.

ADJUSTMENT

BRAKE PEDAL

Loosen lock nut, turn push rod clevis, and adjust push rod length so that height of pedal, measured from pedal pad to floor, is 8.11" (206 mm). NOTE - Make sure pedal stopper (stop light switch) does not contact pedal arm at this time. With push rod adjusted, adjust stop light switch until pedal height is reduced to 7.99" (203 mm).

FRONT DISC BRAKE PADS

Front disc brakes are self-adjusting, therefore, no adjustment in service is required.

REAR DRUM BRAKE SHOES

Rear drum brakes are self-adjusting (actuated by parking brake), therefore, no adjustment in service is required.

PARKING BRAKE

COMBINATION VALVE

Function Test - Accelerate engine to 30 mph and quickly apply brakes. If rear wheels lock before front wheels, malfunction of combination valve is indicated.

Warning Light Operation and Reset -Instrument panel light will come on when a pressure difference of between 71 - 244 psi is evident between front and rear hydraulic systems. Combination valve shuttle moves to side of low pressure and grounds electrical circuit, causing warning light to come on. When hydraulic problem has been corrected and brake have been bled, system should have normal psi. Shuttle will then return to position and light will go out.

REMOVAL & INSTALLATION

FRONT DISC BRAKE PADS

Removal - Remove tire and wheel. Remove clip, retaining pin, damper spring and remove pad with shim.

Installation - Depress piston into cylinder so new pad may be inserted. Install pad, shim, damper spring and retaining pin securing with clip. Depress pedal several times to position new pads.

FRONT DISC BRAKE CALIPER

Removal - With disc pads removed, disconnect hydraulic line from caliper and plug openings. Remove caliper mounting bolts and separate caliper from steering knuckle and rotor.

Installation - Reverse removal procedure, tighten caliper mounting bolts securely, and bleed hydraulic system.

FRONT DISC BRAKE ROTOR

Removal - Remove tire. Pull off brake drum. If drum is hard to remove, apply parking brake and drive out clevis pin. Release brake and pull on drum. Once drum is removed, disconnect all springs, clips and release brake shoes. Wheel cylinders are now accessible.

Installation - Apply brake grease to adjuster and pivot joints on backing plate. Refit brake shoes, springs, and clips. Refit drum. Connect parking brake and continually apply until click sound from adjuster is gone.

REAR WHEEL CYLINDER

Removal - Remove rear brake shoes. Disconnect and plug hydraulic line. Separate parking brake linkage. Remove mounting bolt and slide off cylinder.

Installation - Reverse removal procedure and note the following: Apply brake grease (or equivalent) to wheel cylinder, backing plate, and adjusting sliding surfaces; also lubricate wheel cylinder lever fulcrum and ensure wheel cylinder assembly operates freely.

MASTER CYLINDER

Removal - Disconnect power unit push rod from brake pedal by removing clevis pin. Disconnect hydraulic lines from master cylinder, vacuum line from power unit, remove master cylinder mounting nuts, and remove master cylinder. Remove nuts attaching power unit to firewall, and remove power unit from engine compartment.

Installation - Reverse removal procedure, adjust brake pedal height, and bleed hydraulic system.

Check Valve Replacement - Check valve is located in vacuum line between intake manifold and power unit on firewall. To remove, disconnect retaining clip from firewall, remove hose clamps, separate hoses from valve, and remove check valve. To install, reverse removal procedure.

COMBINATION VALVE

Removal - Disconnect all hydraulic lines from combination valve. Plug openings. Remove mounting bolts and take off valve.

NOTE - 280Z combination valve looks similar to some used on other models. DO NOT mix-up or interchange valves.

Installation - To install, reverse removal procedure note: "F" mark indicates where front brake circuit is attached. Arrows indicate where to attach rear brake circuit. Note there are arrows to show where inlet and outlet lines attach.

OVERHAUL

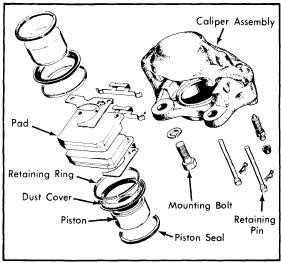

FRONT DISC BRAKE CALIPER

Disassembly - Clean exterior of brake caliper. Remove retaining ring and dust seal. Using a small block of wood, (or equivalent), hold one piston and blow air into brake line inlet to force piston from bore. Remove piston seal from cylinder bore. Remove other piston in similar manner.

Cleaning & Inspection - Clean all parts in alcohol brake fluid. CAUTION - DO NOT use mineral based solvents. Inspect caliper bores for wear, rust, corrosion, or other damage; minor deposits or scratches may be removed with fine emery cloth. Check piston for wear or damage. NOTE - DO NOT use abrasives on piston plated surfaces.

Reassembly - NOTE - Manufacturer recommends replacing rubber parts whenever caliper is being overhauled. Coat piston seal with rubber grease and install into caliper bore. Install dust seal on piston, insert piston into caliper, and install retaining ring. Install opposite piston assembly in same manner.

REAR WHEEL CYLINDER

Disassembly - Remove dust boots. Pull out cylinder pistons and return spring.

Cleaning & Inspection - Clan all parts in alcohol or brake fluid. CAUTION - DO NOT use mineral based solvents. Check all parts for wear or damage; replace parts as necessary. Check clearance between cylinder bore and piston; if clearance exceeds .006", replace cylinder or piston as necessary. Check spring for damage or distortion. NOTE -Manufacturer recommends replacing seal whenever wheel cylinder has been disassembled.

Reassembly - Reverse disassembly procedure and note the following: Apply rubber grease to all parts when reassembling to prevent damage.

MASTER CYLINDER

Disassembly - Remove reservoir filler caps, drain brake fluid, and remove secondary piston stop bolt. Remove snap ring and withdraw primary piston, secondary piston and return spring. Remove valve caps and withdraw check valve assemblies. NOTE - Do not remove reservoirs unless necessary.

Cleaning & Inspection - Clean all parts in alcohol or brake fluid and inspect for wear or damage. Check clearance between cylinder bore and pistons; if clearance exceeds .006" replace cylinder or pistons as necessary. NOTE - Manufacturer recommends replacing piston cups, gaskets, and valves whenever master cylinder has been disassembled.

Reassembly - Reverse disassembly procedure and note the following: Apply rubber grease to all rubber parts and brake fluid to remaining parts when assembling to prevent damage.

POWER BRAKE UNIT.

Disassembly - 1) Place power unit in a soft jawed vise with operating rod pointing up. Scribe alignment marks on front and rear shells to assure reassembly in original position. Remove operating rod lock nut and clevis, then remove dust boot from rear shell.

2) Place a suitable wrench (ST08080000) over rear shell mounting stud. Press down on wrench while rotating counterclockwise and remove rear shell, then remove diaphragm plate assembly, diaphragm spring and push rod assembly. Pry off retainer and remove bearing and valve body seal from rear shell.

3) Remove diaphragm from diaphragm plate assembly, then pry off air silencer retainer and remove silencer and filter. Rotate diaphragm plate assembly until valve plunger key slot is down, then press in on plunger and shake out stop key. Remove reaction disc from plate assembly. Detach flange from front shell and remove plate and seal assembly.

Cleaning & Inspection - Clean all parts in denatured alcohol and blow dry with compressed air. Inspect inside of front and rear shells for wear or damage and replace as necessary. If slight rust is found on inside surface of shells, polish clean with fine emery cloth. Inspect all parts for cracks, nicks, distortion or other damage and replace as necessary.

Reassembly - Reverse disassembly procedure and note the following: Apply a thin coat of silicone grease parts before installation. When assembling front shell to rear shell ensure marks made at disassembly are aligned. After reassembly, measure distance from master cylinder mounting surface to end of power unit push rod; distance should be .38 - .39" (9.8 - 10.0 mm).If distance is not to specifications, correct by adjusting end of push rod.

3 comments:

I would rate this blog 9.5 out of 10. The stepwise process to repair machines is very effective and efficient.

Thanks

Henry Jordan

Hydraulic Seal Kits

free download pdf Datsun workshop manuals http://www.cardiagn.com/category/datsun-repair-service-manuals/

Very nice blog post... Excellent information.

we're committed to helping you ease some of your stress by bringing your vehicle back to its pre-accident condition. We're an MPI-accredited collision repair shop providing complete automotive collision repair services for all kinds of cars, including hybrid cars, so you can get back to your routine in no time.

Direct repair mpi winnipeg

Windshield Repair Winnipeg

Post a Comment